Page 99 - MISUMI SINGAPORE Economy Series

P. 99

1 Economy series Product Overview Product Overview Economy series 1

Lead Screws

Lead Screws

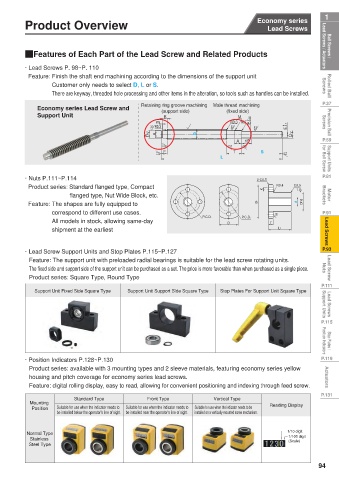

Ball Screws / Lead Screws / Actuators vs Standard Type QFeatures of Each Part of the Lead Screw and Related Products Lead Screws / Actuators Ball Screws /

Saving

up to

Feature: Finish the shaft end machining according to the dimensions of the support unit

Rolled Ball Screws Economy series 80 % · Lead Screws P. 98~P. 110 Screws Rolled Ball

Lead Screw and

Customer only needs to select D, L or S.

There are keyway, threaded hole processing and other items in the alteration, so tools such as handles can be installed.

P.37 Related Products Economy series Lead Screw and Retaining ring groove machining Male thread machining P.37

Precision Ball Screws Semi-finished screws in stock Support Unit 3.2 R0.3 B R0.3 R0.3 0 E-0.05 6.3 0 E-0.1 Screws Precision Ball

(support side)

(fixed side)

M

m

3.2

P.59 Easy design, greatly reducing Rh7 e 3.2 D 3.2 A 15 Qh7 P.59

design time

Support Units for Ball Screw 3.2 F L T S 6.3 for Ball Screw Support Units

6.3

P.81 · Nuts P.111~P.114 2-C0.5 R0.4 C0.5 P.81

Motor Brackets QAllowing to significantly reduce the design time of the lead screw rotating unit Product series: Standard flanged type, Compact K 1.6 Brackets Motor

flanged type, Nut Wide Block, etc.

Economy series standardized parts · Standardize support unit Feature: The shapes are fully equipped to D1 d Dh8

Standardize the special "support unit" for lead screw.

P.91 Lead Screws There is no need to design the bearing mechanism. correspond to different use cases. P.C.D. P.C.D. 1.6 P.91

All models in stock, allowing same-day

Lead Screws Stop Plates · Standardize the shape of lead screw shaft end shipment at the earliest D T L1 Lead Screws

If the shaft diameter and length are determined, they

can be combined directly with the support unit.

P.93 Fixed Side Support Side There is no need for complicated shaft end shape · Lead Screw Support Units and Stop Plates P.115~P.127 P.93

design.

Support Unit

Lead Screw Nuts Support Unit · No need for combination design of various parts Feature: The support unit with preloaded radial bearings is suitable for the lead screw rotating units. Nuts Lead Screw

If the specifications of each part are met, it can be

The fixed side and support side of the support unit can be purchased as a set. The price is more favorable than when purchased as a single piece.

The lead screw rotating unit

assembled directly.

can be completed only by

various parts.

P.111 Position Indicators selecting standard parts. There is no need for complicated combination design of Product series: Square Type, Round Type Stop Plates For Support Unit Square Type P.111

Support Unit Support Side Square Type

Support Unit Fixed Side Square Type

Lead Screws Support Units QReference thread tooth shape of Lead Screws (30 Degree Trapezoidal) Support Units Lead Screws

P.115 H=1.866P H1=0.5P d2=d-0.5P d1=d-P D=d D2=d2 D1=d1 P.115

Stop Plates / Position Indicators H/2 H1/2 Female Thread Male Thread Position Indicators Stop Plates /

15° 15°

P.119 H H/2 H1 Male Thread d1 or D1 d2 or D2 d or D d: O.D. d1: Thread bottom dia. d2: Effective dia. · Position Indicators P.128~P.130 P.119

30°

Female Thread

Product series: available with 3 mounting types and 2 sleeve materials, featuring economy series yellow

Actuators P D: Thread bottom dia. D1: I.D. D2: Effective dia. P: Pitch H1: Height of screwing part housing and pitch coverage for economy series lead screws. Actuators

Feature: digital rolling display, easy to read, allowing for convenient positioning and indexing through feed screw.

P.131 QLead screw specification accuracy Standard Type Front Type Vertical Type P.131

Mounting Reading Display

QRunout Measurement Method Position Suitable for use when the indicator needs to Suitable for use when the indicator needs to Suitable for use when the indicator needs to be

Item Content be installed below the operator’s line of sight. be installed near the operator’s line of sight. installed on a vertically-mounted screw mechanism.

Screw accuracy Class 7e

Nut accuracy Class 7H 1/10 digit

D Normal Type 1/100 digit

Single pitch error ±0.02 Stainless (Scale)

Steel Type

Accumulated pitch error ±0.15/300mm

Total length runout tolerance See P. 96 Table (20) (20)

94