Page 102 - MISUMI SINGAPORE Economy Series

P. 102

1 Economy series Alteration Options 1

Lead Screws

Ball Screws / Lead Screws / Actuators QAlteration Options Lead Screws / Actuators Ball Screws /

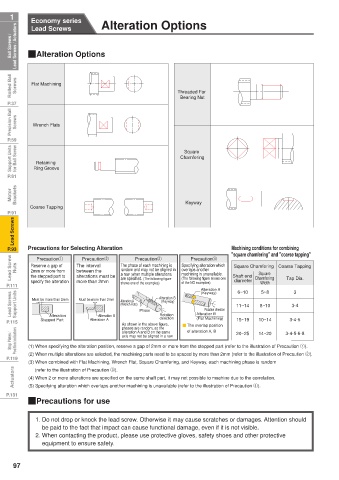

Rolled Ball Screws Flat Machining Threaded For Screws Rolled Ball

P.37 Bearing Nut P.37

Precision Ball Screws Wrench Flats Screws Precision Ball

P.59 P.59

Support Units for Ball Screw Retaining Chamfering for Ball Screw Support Units

Square

P.81 Ring Groove P.81

Motor Brackets Brackets Motor

Coarse Tapping Keyway

P.91 P.91

Lead Screws Lead Screws

P.93 Precautions for Selecting Alteration Machining conditions for combining P.93

"square chamfering" and "coarse tapping"

Lead Screw Nuts Reserve a gap of The interval The phase of each machining is Specifying alteration which Shaft end Square Coarse Tapping Nuts Lead Screw

Precaution1

Precaution4

Precaution2

Precaution3

Square Chamfering

overlaps another

random and may not be aligned in

between the

2mm or more from

a row ,when multiple alterations

machining is unavailable.

alterations must be

the stepped part to

Width

shows one of the examples)

of the NG examples)

P.111 specify the alteration more than 2mm are specified. (The following figure (The following figure shows one diameter Chamfering Tap Dia. P.111

Alteration A

6~10

5~8

3

(Keyway)

Lead Screws Support Units Must be more than 2mm Must be more than 2mm Alteration A Phase Alteration B Rotation direction 11~14 8~10 3·4 Support Units Lead Screws

(Keyway)

(Wrench Flats)

Alteration B

Rotation

Alteration

Alteration B

direction

(Flat Machining)

P.115 Stepped Part Alteration A As shown in the above figure, The overlap position 15~19 10~14 3·4·5 P.115

phases are random, so the

of alteration A, B

alteration A and B on the same

14~20

20~25

3·4·5·6·8

Stop Plates / Position Indicators (1) When specifying the alteration position, reserve a gap of 2mm or more from the stepped part (refer to the illustration of Precaution 1). Position Indicators Stop Plates /

axis may not be aligned in a row.

P.119 (2) When multiple alterations are selected, the machining parts need to be spaced by more than 2mm (refer to the illustration of Precaution 2). P.119

(3) When combined with Flat Machining, Wrench Flat, Square Chamfering, and Keyway, each machining phase is random

(refer to the illustration of Precaution 3).

Actuators (4) When 2 or more alterations are specified on the same shaft part, it may not possible to machine due to the correlation. Actuators

(5) Specifying alteration which overlaps another machining is unavailable (refer to the illustration of Precaution 4).

P.131 P.131

QPrecautions for use

1. Do not drop or knock the lead screw. Otherwise it may cause scratches or damages. Attention should

be paid to the fact that impact can cause functional damage, even if it is not visible.

2. When contacting the product, please use protective gloves, safety shoes and other protective

equipment to ensure safety.

97