Page 47 - MISUMI SINGAPORE Economy Series

P. 47

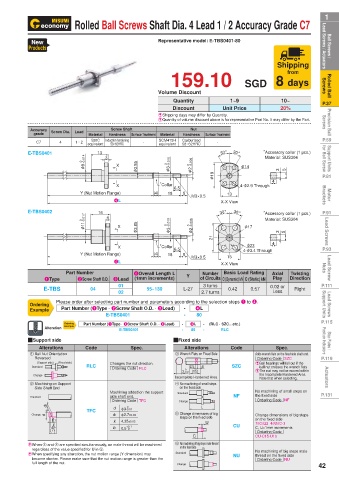

1 Rolled Ball Screws Shaft Dia. 4 Lead 1 / 2 Accuracy Grade C7 1

Ball Screws / Lead Screws / Actuators Products Representative model: E-TBS0401-80 Shipping Lead Screws / Actuators Ball Screws /

New

159.10

from

Rolled Ball Screws Volume Discount SGD 8 days Screws Rolled Ball

Quantity

10~

1~9

P.37 Discount Unit Price 20% P.37

Precision Ball Screws Accuracy Screw Shaft E Shipping days may differ by Quantity. Screws Precision Ball

E Quantity of volume discount above is for representative Part No. It may differ by the Part.

Nut

Material

Hardness

Material

Hardness

P.59 grade Screw Dia. Lead equivalent Induction hardening Surface Treatment SCM415H 58~62HRC Surface Treatment P.59

Carburized

S55C

-

-

C7

4

1 · 2

equivalent

58~62HRC

Support Units for Ball Screw E-TBS0401 0 -0.014 13 3 X 0 -0.010 0 -0.008 30° 30° φ 14 * Accessory collar (1 pcs.) for Ball Screw Support Units

Material: SUS304

P.81 φ 9 φ 3.85 φ 3 φ 2 φ 19 4 3 5 P.81

X * Collar 6.5 4- φ 2.9 Through

Motor Brackets Y (Nut Motion Range) (4) 18 5 M3×0.5 X-X View Brackets Motor

13

4L

P.91 E-TBS0402 0 -0.017 16 4 30° 30° * Accessory collar (1 pcs.) P.91

Material: SUS304

Lead Screws φ 11 X φ 3.85 0 -0.010 φ 3 0 -0.008 φ 2 21 φ 17 3 5 Lead Screws

φ 23

P.93 Y (Nut Motion Range) X (4) * Collar 6.5 5 M3×0.5 15 4- φ 3.4 Through 4 P.93

18

Lead Screw Nuts Part Number 4L 4Overall Length L Y Number Basic Load Rating Axial Twisting Nuts Lead Screw

X-X View

Play

1Type

P.111 E-TBS 2Screw Shaft O.D. 3Lead (1mm increments) L-27 of Circuits C (Dynamic) kN C (Static) kN 0.02 or Direction P.111

01

3 turns

55~130

0.57

04

Right

0.42

Less

02

2.7 turns

Lead Screws Support Units Ordering Please order after selecting part number and parameters according to the selection steps 1 to 4. Support Units Lead Screws

4L

-

Part Number (1Type · 2Screw Shaft O.D. · 3Lead)

Example

E-TBS0401

P.115 Alteration Ordering Part Number (1Type · 2Screw Shaft O.D. · 3Lead) - - - 4L 80 - - (RLC · SZC…etc.) P.115

Example

80

RLC

E-TBS0401

Stop Plates / Position Indicators QSupport side Code Spec. QFixed side Code Spec. Position Indicators Stop Plates /

Alterations

Alterations

5

1

P.119 1 Ball Nut Orientation 3 Wrench Flats on Fixed Side Adds wrench flats on the fixed side shaft end. P.119

Reversed

Ordering Code SZC

(Support side) (Fixed side) RLC Changes the nut direction. 0 2.5 4 SZC E Ball bearings will fall out if the

ball nut crosses the wrench flats

Standard

Ordering Code RLC

Actuators 2 Machining on Support Incomplete Hardened Area E The nut may not be moved within Actuators

(15)

3-0.2

the Incomplete Hardened Area.

Change

Note that when selecting.

4 No machining of small steps

on the fixed side

Side Shaft End

P.131 Standard Machining added on the support Standard NF No machining of small steps on P.131

the fixed side

side shaft end.

Ordering Code TFC Change Ordering Code NF

d1 d 0 L

TFC φ3-0.01

Change d d1 φ2.7±0.03 5 Change dimensions of big Change dimensions of big steps

steps on the fixed side

L1 L 4.35±0.05 U on the fixed side

L +0.1 CU 7≤C≤22 4≤U≤C-3

(7) L1 0.5 0 C, U=1mm increments

Ordering Code

C CU-C15-U10

E When 5 and 6 are specified simultaneously, no male thread will be machined 6 No machining of big steps male thread

regardless of the value specified for U in 5. on the fixed side No machining of big steps male

E When specifying any alteration, the nut motion range (Y dimension) may Standard NU thread on the fixed side

become shorter. Please make sure that the nut motion range is greater than the Ordering Code NU

full length of the nut. Change 42