Page 44 - MISUMI SINGAPORE Economy Series

P. 44

1 Economy series Alteration Options / Peripheral Products Lead Accuracy Grade Economy series 1

Ball Screws

Ball Screws

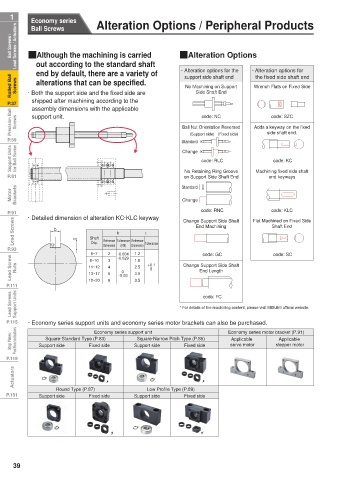

Ball Screws / Lead Screws / Actuators QAlthough the machining is carried QAlteration Options QBall Screw Lead Precision Lead Screws / Actuators Ball Screws /

out according to the standard shaft

Screw Effective Length (lu)

end by default, there are a variety of

error (±ep) and variation (Vu)

Rolled Ball Screws · Both the support side and the fixed side are · Alteration options for the · Alteration options for + Actual Travel Representative Travel Standard Travel Allowable value of representative travel Representative Unit: μm Screws Rolled Ball

Nominal Travel

support side shaft end

the fixed side shaft end

alterations that can be specified.

Distance (la) Line

Distance (lo) Line

Accuracy grade

Screw Effective

Wrench Flats on Fixed Side

No Machining on Support

Length (mm)

C5 (Economy series)

C3

Distance (lm) Line

Distance (ls) Line

Side Shaft End

Representative

Error

Error

P.37 shipped after machining according to the 0’ 0 t More than or Less Travel Distance Variation Travel Distance Variation P.37

23

12

8

18

315

assembly dimensions with the applicable

Precision Ball Screws support unit. Ball Nut Orientation Reversed Adds a keyway on the fixed Travel Distance Error - v 300 315 400 13 10 25 20 Screws Precision Ball

code: SZC

code: NC

500

20

400

15

10

27

23

30

12

630

16

500

(Support side) (Fixed side)

800

630

P.59 Standard side shaft end. 2π v2π 300mm vu ep 1000 1000 18 13 35 25 P.59

15

800

40

21

27

Support Units for Ball Screw Change code: RLC code: KC 1250 1600 29 18 54 35 for Ball Screw Support Units

24

46

16

1250

30

No Retaining Ring Groove

300mm and pitch periodic error (V2π)

end keyways

P.81 on Support Side Shaft End Machining fixed side shaft Standard value of variation (V300) relative to displacement Unit: μm P.81

Accuracy grade C3 C5 (Economy series) C7 (Economy series) C10

Standard

Item

Motor Brackets Change Standard value V300 V2π V300 V2π V300 V300 Brackets Motor

8

18

6

52

210

8

code: RNC

code: KLC

based on ep=2·lu/300·V300.

P.91 · Detailed dimension of alteration KC·KLC keyway Change Support Side Shaft Flat Machined on Fixed Side EC7(Economy series) representative distance error (ep) can be calculated P.91

Lead Screws b t Shaft b t End Machining Shaft End Lead Screws

Reference Tolerance Reference

(N9)

P.93 6.3 Dia. Dimension -0.004 Dimension Tolerance code: GC code: SC P.93

6~7

2

1.2

Lead Screw Nuts 11~12 3 4 5 -0.03 1.8 +0.1 Change Support Side Shaft Nuts Lead Screw

-0.029

8~10

2.5

0

End Length

0

13~17

3.0

P.111 18~20 6 3.5 Allowable Axial Load Line Diagram Allowable Rotational Speed Line Diagram P.111

Lead Screws Support Units * For details of the machining content, please visit MISUMI official website. 3 2 6 5 4 3 2 10 5 φ32 1.5 3 2 10 2 4 10 1.5 8 4 10 4 8 6 5 4 φ 10 φ 15 Screw shaft O.D. (mm) Support Units Lead Screws

code: FC

1.5

1.5

φ 20

P.115 · Economy series support units and economy series motor brackets can also be purchased. 1.5 8 4 1.5 3 2 1.5 8 5 8 6 5 4 φ20 φ25 10 8 6 5 3 8 6 5 4 6 5 4 3 1.5 3 2 φ 25 φ 32 P.115

10

10

Economy series support unit

Stop Plates / Position Indicators Support side Fixed side Support side Fixed side Economy series motor bracket (P.91) 6 5 4 10 8 6 5 6 5 4 3 1.5 3 2 φ15 4 3 2 1.5 3 2 1.5 2 3 10 8 6 5 3 Position Indicators Stop Plates /

Square-Standard Type (P.83)

Square-Narrow Pitch Type (P.85)

Applicable

Applicable

stepper motor

servo motor

10

10

P.119 Allowable Axial Load (N) 1.5 3 2 5 4 3 1.5 2 10000N 4 8 6 φ10 Allowable Rotational Speed (min -1 ) 1.5 8 2 10 8 6 5 3 8 6 5 4 3 4 3 2 P.119

10

Actuators 10 8 3 1.5 2 4 10 8 6 5 4 4 3 6 5 4 3 4 3 2 1.5 2 1.5 8 2 Actuators

10

10

Round Type (P.87) Low Profile Type (P.89) 6 5 8 4 2 2 1.5 10 2 6 5

P.131 Support side Fixed side Support side Fixed side 4 6 3 1.5 1.5 10 2 8 6 4 P.131

3 5 8 5 3

4 2 10 3 10 6 4

10 2 1.5 2 3 4 5 6 7 8 9 10 3 1.5 2 3 4 5 6 7 8 5 3 2

10

2

Fixed - Fixed - Fixed - Supported - Fixed - Fixed - Fixed - Supported - 1.5 2 3 4 5 6 7 8 910 3 1.5 2 3 4 5 6 7

Free Fixed Supported Supported Load action point pitch (mm) Free Fixed Supported Supported Support pitch (mm)

Support method Support method

39