Page 46 - MISUMI SINGAPORE Economy Series

P. 46

1 Economy series Runout Tolerance / Precautions 1

Ball Screws

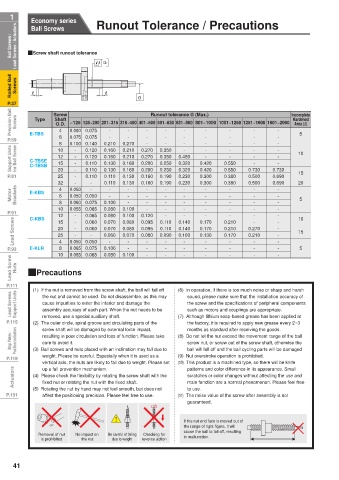

Ball Screws / Lead Screws / Actuators QScrew shaft runout tolerance G Lead Screws / Actuators Ball Screws /

Rolled Ball Screws L L Screws Rolled Ball

P.37 G P.37

Precision Ball Screws Type Screw 0.060 0.075 - - - Runout tolerance G (Max.) - - - Incomplete Screws Precision Ball

Shaft

Hardened

~125 126~200 201~315 316~400 401~500 501~630 631~800 801~1000 1001~1250 1251~1600 1601~2000

O.D.

Area (L)

4

-

-

-

-

-

P.59 E-TBS 6 8 0.075 0.075 0.210 0.270 - - - - - - - - - - - - - - 5 P.59

0.100 0.140

Support Units for Ball Screw C-TBSE 10 - - - 0.120 0.160 0.210 0.270 0.350 0.480 0.420 0.550 - - - - - - 10 for Ball Screw Support Units

-

-

-

0.350

0.270

-

12

0.120

0.160

0.210

-

0.110

0.130

0.160

15

0.320

0.250

0.200

C-TBSB

0.110

0.690

0.380

P.81 20 - - 0.110 0.130 0.160 0.200 0.250 0.320 0.420 0.550 0.730 0.730 15 P.81

0.300

0.500

0.160

0.110

25

0.230

0.190

0.130

32 - - 0.110 0.130 0.160 0.190 0.230 0.300 0.380 0.500 0.690 20

Motor Brackets E-KBS 4 6 0.050 - - - - - - - - - - - - - - - - - - - 5 Brackets Motor

0.050 0.050

-

8

0.080

0.055 0.065

10 0.060 0.075 0.100 0.100 - - - - - - - - - - - - - -

P.91 C-KBS 12 - - 0.065 0.080 0.100 0.120 0.110 0.140 0.170 0.210 - - - - 10 P.91

-

-

-

-

Lead Screws 20 - - 0.060 0.070 0.080 0.095 0.090 0.140 0.170 0.210 0.270 - - 15 Lead Screws

0.080

15

0.095

0.070

0.060

0.110

-

0.130

0.100

0.170

0.060

25

0.070

0.080

0.210

-

4

-

-

0.065 0.075

8

P.93 E-KLR 10 0.050 0.050 0.100 0.100 - - - - - - - - - - - - - - - - - - - - - 5 P.93

0.065 0.065

0.080

Lead Screw Nuts QPrecautions Nuts Lead Screw

P.111 (1) If the nut is removed from the screw shaft, the ball will fall off (6) In operation, if there is too much noise or sharp and harsh P.111

Lead Screws Support Units the nut and cannot be used. Do not disassemble, as this may sound, please make sure that the installation accuracy of Support Units Lead Screws

the screw and the specifications of peripheral components

cause impurities to enter the interior and damage the

assembly accuracy of each part. When the nut needs to be

such as motors and couplings are appropriate.

removed, use a special auxiliary shaft.

P.115 (2) The outer circle, spiral groove and circulating parts of the (7) Although lithium soap-based grease has been applied at P.115

the factory, it is required to apply new grease every 2~3

months as standard after receiving the goods.

screw shaft will be damaged by external force impact,

Stop Plates / Position Indicators (3) Ball screws and nuts placed with an inclination may fall due to (8) Do not let the nut exceed the movement range of the ball Position Indicators Stop Plates /

resulting in poor circulation and loss of function. Please take

screw nut, or screw out of the screw shaft, otherwise the

care to avoid it.

ball will fall off and the ball cycling parts will be damaged.

P.119 weight. Please be careful. Especially when it is used as a (9) Nut overstroke operation is prohibited. P.119

vertical axis, the nuts are likely to fall due to weight. Please set (10) This product is a machined type, so there will be knife

patterns and color difference in its appearance. Small

up a fall prevention mechanism.

Actuators (4) Please check the flexibility by rotating the screw shaft with the scratches or color changes without affecting the use and Actuators

fixed nut or rotating the nut with the fixed shaft.

main function are a normal phenomenon. Please feel free

to use.

P.131 (5) Rotating the nut by hand may not feel smooth, but does not (11) The noise value of the screw after assembly is not P.131

affect the positioning precision. Please feel free to use.

guaranteed.

If the nut end face is moved out of

the range of right figure, it will

cause the ball to fall off, resulting

Removal of nut No impact on Be careful of falling Checking for

is prohibited the nut due to weight reverse action in malfunction.

41