Page 211 - MISUMI SINGAPORE Economy Series

P. 211

1 1

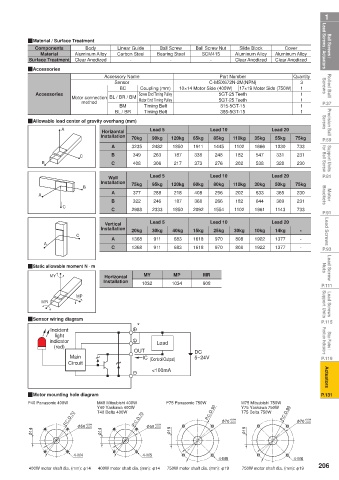

Ball Screws / Lead Screws / Actuators QMaterial / Surface Treatment Carbon Steel Bearing Steel Ball Screw Nut Aluminum Alloy Aluminum Alloy Lead Screws / Actuators Ball Screws /

Slide Block

Ball Screw

Components

Cover

Linear Guide

Body

Aluminum Alloy

Material

SCM415

Clear Anodized

Surface Treatment

Clear Anodized

-

-

Clear Anodized

-

Rolled Ball Screws QAccessories Accessory Name Screw End Timing Pulley 10×14 Motor Side (400W) 17×19 Motor Side (750W) Quantity Screws Rolled Ball

Part Number

Sensor

3

C-MSX672N-2M(NPN)

BC

1

Coupling (mm)

5GT-25 Teeth

1

Accessories

method

P.37 Motor connection BL / BR / BM Motor End Timing Pulley 5GT-25 Teeth 1 1 1 P.37

Timing Belt

BM

315-5GT-15

Precision Ball Screws QAllowable load center of gravity overhang (mm) Lead 5 Lead 10 Lead 20 Screws Precision Ball

BL / BR

Timing Belt

385-5GT-15

A

Horizontal

P.59 Installation 70kg 90kg 120kg 65kg 85kg 110kg 35kg 55kg 75kg P.59

1850

3235

1666

Support Units for Ball Screw B C B 349 263 187 338 248 182 547 331 231 for Ball Screw Support Units

1911

733

1030

1445

2482

1102

A

276

373

217

408

306

230

202

328

C

538

P.81 Wall Lead 5 Lead 10 Lead 20 P.81

Installation 75kg 95kg 120kg 60kg 80kg 110kg 30kg 50kg 75kg

B

Motor Brackets A A 377 288 218 408 296 202 633 365 230 Brackets Motor

231

187

266

368

369

182

246

B

322

644

C C 2988 2333 1850 2092 1554 1102 1961 1143 733

P.91 Lead 5 Lead 10 Lead 20 P.91

Lead Screws C Installation 20kg 30kg 40kg 15kg 25kg 30kg 10kg 14kg - - Lead Screws

Vertical

1377

970

808

1922

A

911

1368

1618

683

P.93 A C 1368 911 683 1618 970 808 1922 1377 - P.93

Lead Screw Nuts QStatic allowable moment N · m MY MP MR Nuts Lead Screw

MY

Horizontal

P.111 Installation 1032 1034 908 P.111

Lead Screws Support Units MR MP Support Units Lead Screws

P.115 QSensor wiring diagram * P.115

Incident

Stop Plates / Position Indicators indicator Load Position Indicators Stop Plates /

light

(red)

5~24V

P.119 Main OUT IC (Control Output) DC P.119

Circuit <100mA

Actuators Actuators

P.131 QMotor mounting hole diagram P.131

P40 Panasonic 400W M40 Mitsubishi 400W P75 Panasonic 750W M75 Mitsubishi 750W

Y40 Yaskawa 400W P.C.D.90 Y75 Yaskawa 750W

T40 Delta 400W

T75 Delta 750W

P.C.D.70 +0.04 P.C.D.70 +0.04 φ 70 +0.01 P.C.D.90 φ 70 +0.01

+0.04

+0.04

φ 14 φ 50 +0.01 φ 14 φ 50 +0.01 φ 19 φ 19

4-M4 4-M5

4-M5 4-M6

206

400W motor shaft dia. (mm): φ14 400W motor shaft dia. (mm): φ14 750W motor shaft dia. (mm): φ19 750W motor shaft dia. (mm): φ19