Page 207 - MISUMI SINGAPORE Economy Series

P. 207

1 1

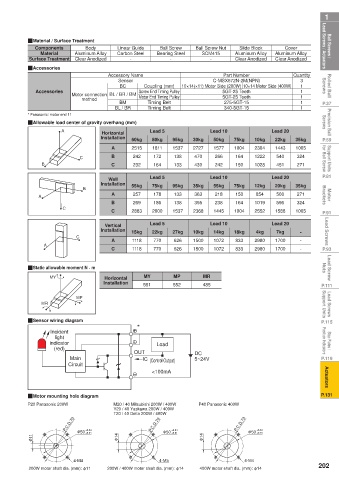

Ball Screws / Lead Screws / Actuators QMaterial / Surface Treatment Carbon Steel Bearing Steel Ball Screw Nut Aluminum Alloy Aluminum Alloy Lead Screws / Actuators Ball Screws /

Slide Block

Components

Ball Screw

Cover

Body

Linear Guide

Aluminum Alloy

Material

SCM415

-

Surface Treatment

Clear Anodized

-

Clear Anodized

Clear Anodized

-

Part Number

Accessory Name

Rolled Ball Screws QAccessories Motor connection BL / BR / BM Screw End Timing Pulley 10×14(×11) Motor Side (200W) 10×14 Motor Side (400W) Quantity Screws Rolled Ball

C-MSX672N-2M(NPN)

Sensor

3

1

BC

Coupling (mm)

1

5GT-25 Teeth

Accessories

Timing Belt

275-5GT-15

BM

P.37 method BL / BR Motor End Timing Pulley 5GT-25 Teeth 1 1 1 P.37

340-5GT-15

Timing Belt

Precision Ball Screws * Panasonic: motor end 11 Screws Precision Ball

QAllowable load center of gravity overhang (mm)

Horizontal

80kg

22kg

P.59 A Installation 60kg Lead 5 95kg 30kg Lead 10 75kg 10kg Lead 20 35kg P.59

50kg

Support Units for Ball Screw B C B 242 172 138 470 266 164 1222 540 324 for Ball Screw Support Units

A

2727

1811

1537

2515

1577

1004

2304

1443

1005

1028

164

271

242

430

133

451

150

232

C

P.81 Wall Lead 5 Lead 10 Lead 20 P.81

Installation 55kg 75kg 95kg 35kg 55kg 75kg 12kg 20kg 35kg

B

Motor Brackets A A 257 178 133 363 218 150 854 500 271 Brackets Motor

C B 269 186 138 395 238 164 1019 596 324

P.91 C 2883 2000 1537 2368 1445 1004 2552 1588 1005 P.91

Lead Screws C Installation 15kg Lead 5 27kg 10kg Lead 10 18kg 4kg Lead 20 - Lead Screws

Vertical

14kg

22kg

7kg

1700

1072

C

833

P.93 A A 1118 770 626 1500 1072 833 2980 1700 - - P.93

2980

1118

770

626

1500

Lead Screw Nuts QStatic allowable moment N · m MY MP MR Nuts Lead Screw

Horizontal

P.111 MY Installation 551 552 485 P.111

Lead Screws Support Units MR MP Support Units Lead Screws

P.115 QSensor wiring diagram * P.115

Incident

Stop Plates / Position Indicators indicator Load Position Indicators Stop Plates /

light

(red)

5~24V

P.119 Main OUT IC (Control Output) DC P.119

Circuit

Actuators <100mA Actuators

P.131 QMotor mounting hole diagram P.131

P20 Panasonic 200W M20 / 40 Mitsubishi 200W / 400W P40 Panasonic 400W

Y20 / 40 Yaskawa 200W / 400W

T20 / 40 Delta 200W / 400W

P.C.D.70 P.C.D.70 P.C.D.70

+0.04

+0.04

+0.04

φ 50 +0.01 φ 50 +0.01 φ 50 +0.01

φ 11 φ 14 φ 14

4-M4 4-M5 4-M4

200W motor shaft dia. (mm): φ11 200W / 400W motor shaft dia. (mm): φ14 400W motor shaft dia. (mm): φ14 202