Page 113 - MISUMI SINGAPORE Economy Series

P. 113

1 1

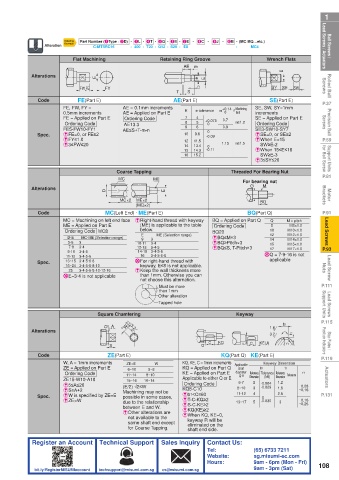

Ball Screws / Lead Screws / Actuators Alteration Ordering Part Number (1Type · 2D) - 3L - 4T - 5Q - 6S - 7E - 8C - 9J - 0B - (MC·MQ…etc.) Lead Screws / Actuators Ball Screws /

Example

C-MTSRC16

MC4

-

- 400 - T20 - Q12 - S20 - E8

Wrench Flats

Flat Machining

Retaining Ring Groove

AE

m

E

Rolled Ball Screws FW FE FY T S e n E SY SE SW Screws Rolled Ball

Alterations

E

SE(Part E)

FE(Part E)

P.37 Code FE, FW, FY = AE = 0.1mm increments AE(Part E) e tolerance m +0.14 n limit SE, SW, SY=1mm P.37

Machining

Precision Ball Screws FE = Applied on Part E AE13.3 7 8 9 4 5 6 +0.075 0.7 n≥1.2 SE = Applied on Part E Screws Precision Ball

E

0.5mm increments

AE = Applied on Part E

0

increments

Ordering Code

Ordering Code

Ordering Code

0

0.9

FE5-FW10-FY1

SE3-SW10-SY7

AE≤S+T-m-n

0

9.6

EFY≤1.0

E When E<15

P.59 Spec. EFE=0, or FE≥2 10 11.5 -0.09 1.15 n≥1.5 ESE=0, or SE≥2 P.59

12

SW≥E-2

E3≤FW≤20

13.4

Support Units for Ball Screw 15 14.3 -0.11 E When 15≤E≤16 for Ball Screw Support Units

14

0

SW≥E-3

15.2

16

E3≤SY≤20

P.81 Coarse Tapping Threaded For Bearing Nut P.81

MC ME For bearing nut

M

Q

Motor Brackets Alterations D MC×2 ME×2 E BQ Brackets Motor

(MQ×2)

BQ(Part Q)

MC(Left End) · ME(Part E)

P.91 Code MC = Machining on left end face E Right-hand thread with keyway BQ = Applied on Part Q Q M x pitch P.91

Lead Screws ME = Applied on Part E (ME) is applicable to the table BQ20 10 M10×1.0 Lead Screws

8

M8×1.0

Ordering Code

below.

Ordering Code MC8

12

M12×1.0

ME (Selection range)

E

EBQ≤M×3

D·E

MC·ME (Selection range)

3

M14×1.0

14

9

5·6

M15×1.0

15

3·4·5

12·13

7·8

EBQ≤S, T-Pitch×3

P.93 11·12 3 3·4 10·11 3·4 EBQ≥Pitch×3 X Q = 7·9·16 is not P.93

17

M17×1.0

9·10

14·15 3·4·5·6

3·4·5

3·4·5·6·8

16

3·4·5·6

Lead Screw Nuts Spec. XE=3·4 is not applicable X For right-hand thread with applicable Nuts Lead Screw

13~15 3·4·5·6·8

keyway, E≤8 is not applicable.

16~24 3·4·5·6·8·10

E Keep the wall thickness more

25

3·4·5·6·8·10·12·16

than 1mm. Otherwise you can

P.111 not choose this alternation. P.111

Must be more

than 1mm

Lead Screws Support Units Other alteration Support Units Lead Screws

Tapped hole

P.115 Square Chamfering Keyway b1 P.115

-0.1

Q A W -0.3 3.2 1.6

Alterations

Stop Plates / Position Indicators S Q C KQ E C KE(J) 3.2 r1 t1 Position Indicators Stop Plates /

P.119 Code ZE(Part E) KQ(Part Q) KE(Part E) P.119

W, A = 1mm increments ZE=E 5~8 W KQ, KE, C = 1mm increments Applicable b1 Keyway Dimension

KQ = Applied on Part Q

ZE = Applied on Part E

shaft

t1

Actuators ZE15-W10-A10 11~14 10~14 KE = Applied on Part E diameter Reference Tolerance Reference Tolerance r1 Actuators

6~10

Ordering Code

8~10

Q·E

(N9)

Dimension

Dimension

Applicable to either Q or E

15~16

6·7

2

1.2

-0.004

Ordering Code

E5≤A≤20

0.08

8~10

Machining may not be

2.5

Eb1<C≤60

P.131 Spec. ES≥A+2 (E/2) √2≤W KQ8-C10 11·12 3 4 -0.029 1.8 ~0.16 P.131

EW is specified by ZE=E

possible in some cases,

0

EZE>W due to the relationship ET-C-KQ≥2 13~17 5 -0.030 3 ~0.25

0.16

between E and W. ES-C-KE≥2

EKQ(KE)≥2

E Other alterations are E When KQ, KE=0,

not available to the

same shaft end except keyway R will be

eliminated on the

for Coarse Tapping. shaft end side.

Register an Account Technical Support Sales Inquiry Contact Us:

Tel: (65) 6733 7211

Website: sg.misumi-ec.com

Hours: 9am - 6pm (Mon - Fri) 108

bit.ly/RegisterMISUMIaccount techsupport@misumi.com.sg cs@misumi.com.sg 9am - 3pm (Sat)