Page 80 - MISUMI SINGAPORE Economy Series

P. 80

1 Economy series Product Overview 1

Left and Right Hand Precision Ball Screws

Ball Screws / Lead Screws / Actuators Lead Screws / Actuators Ball Screws /

Rolled Ball Screws Economy series Left and Right New Screws Rolled Ball

Hand Precision Ball Screws

P.37 Products P.37

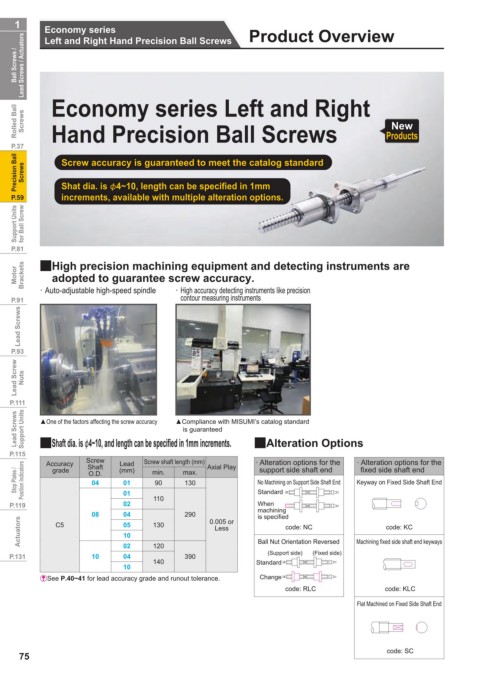

Precision Ball Screws Screw accuracy is guaranteed to meet the catalog standard Screws Precision Ball

increments, available with multiple alteration options.

P.59 Shat dia. is φ4~10, length can be specified in 1mm P.59

Support Units for Ball Screw for Ball Screw Support Units

P.81 P.81

Motor Brackets QHigh precision machining equipment and detecting instruments are Brackets Motor

adopted to guarantee screw accuracy.

contour measuring instruments

P.91 · Auto-adjustable high-speed spindle · High accuracy detecting instruments like precision P.91

Lead Screws Lead Screws

P.93 P.93

Lead Screw Nuts Nuts Lead Screw

P.111 P.111

Lead Screws Support Units ▲One of the factors affecting the screw accuracy ▲Compliance with MISUMI’s catalog standard Support Units Lead Screws

is guaranteed

P.115 QShaft dia. is φ4~10, and length can be specified in 1mm increments. QAlteration Options P.115

Screw

· Alteration options for the

Screw shaft length (mm)

· Alteration options for the

Lead

Accuracy

Axial Play

Shaft

support side shaft end

fixed side shaft end

Stop Plates / Position Indicators grade O.D. (mm) min. max. No Machining on Support Side Shaft End Keyway on Fixed Side Shaft End Position Indicators Stop Plates /

130

04

01

90

Standard

02

P.119 01 110 When P.119

08 04 290 0.005 or machining

is specified

Actuators C5 05 130 Less Ball Nut Orientation Reversed Machining fixed side shaft end keyways Actuators

code: KC

code: NC

10

P.131 10 02 120 390 (Support side) (Fixed side) P.131

04

10 140 Standard

ESee P.40~41 for lead accuracy grade and runout tolerance. Change

code: RLC code: KLC

Flat Machined on Fixed Side Shaft End

code: SC

75