Page 77 - MISUMI SINGAPORE Economy Series

P. 77

1 1

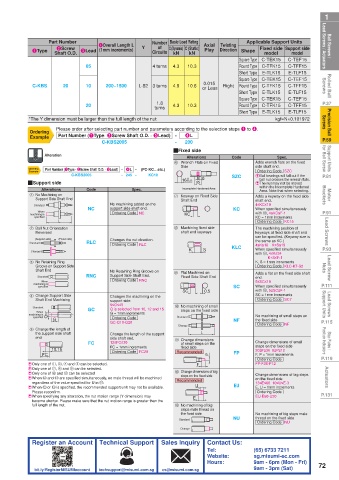

Ball Screws / Lead Screws / Actuators 1Type Part Number 3Lead 4Overall Length L Y Number Basic Load Rating Axial Twisting Square Type C-TEK15 C-TEF15 Lead Screws / Actuators Ball Screws /

Applicable Support Units

of

C (Dynamic) C (Static)

Fixed side Support side

2Screw

Play

(1mm increments)

Direction Shape

Circuits

Shaft O.D.

model

model

kN

kN

4 turns

C-TFF15

E-TLK15

Short Type

E-TLF15

Rolled Ball Screws C-KBS 20 05 200~1500 L-82 3 turns 4.3 10.3 or Less Right Round Type C-TFK15 C-TEF15 Screws Rolled Ball

Square Type C-TEK15

0.015

10

10.6

4.9

Round Type C-TFK15

C-TFF15

Short Type

E-TLK15

E-TLF15

1.8

P.37 20 turns 4.3 10.3 Square Type C-TEK15 C-TEF15 P.37

Round Type C-TFK15

C-TFF15

Precision Ball Screws *The Y dimension must be larger than the full length of the nut kgf=N×0.101972 Screws Precision Ball

Short Type

E-TLF15

E-TLK15

Please order after selecting part number and parameters according to the selection steps 1 to 4.

Example

P.59 Ordering Part Number (1Type· 2Screw Shaft O.D. · 3Lead) - - 4L P.59

C-KBS2005

200

Support Units for Ball Screw Alteration QFixed side Code Adds wrench flats on the fixed for Ball Screw Support Units

Alterations

Spec.

Wrench Flats on Fixed

6

side shaft end.

Side

Ordering Code SZC

Example

- 245 -

KC10

C-KBS2005

P.81 Ordering Part Number (1Type · 2Screw Shaft O.D. · 3Lead) - 4L - (FC·KC…etc.) 0 9 6 SZC E Ball bearings will fall out if the P.81

ball nut crosses the wrench flats.

16

QSupport side Incomplete Hardened Area E The nut may not be moved

-0.25

35

within the Incomplete Hardened

Alterations

Motor Brackets 1 No Machining on Code Spec. 7 Keyway on Fixed Side Adds a keyway on the fixed side Brackets Motor

Area. Note that when selecting.

Support Side Shaft End

Shaft End

shaft end.

Standard

support side shaft end.

NC No machining added on the KC 4≤KC≤19

When specified simultaneously

P.91 machining is L Ordering Code NC KC with Q, 4≤KC≤F-1 P.91

When

specified

KC = 1mm increments

Lead Screws 2 (Support side) (Fixed side) Changes the nut direction. 8 Machining fixed side The machining position of Lead Screws

Ordering Code KC15

Ball Nut Orientation

shaft end keyways

keyways at fixed side shaft end

Reversed

can be specified. (Keyway size is

4≤K≤18 K+S≤19

P.93 Standard RLC Ordering Code RLC K S KLC the same as KC.) P.93

When specified simultaneously

Change

with Q, 4≤K≤34

Lead Screw Nuts 3 No Retaining Ring RNC No Retaining Ring Groove on 9 Flat Machined on K, S = 1mm increments Nuts Lead Screw

K+S≤F-1

Groove on Support Side

Ordering Code KLC-K7-S2

Shaft End

Adds a flat on the fixed side shaft

Support Side Shaft End.

Standard

When

5≤SC≤19

P.111 machining is Ordering Code RNC Fixed Side Shaft End SC end. P.111

When specified simultaneously

specified

0.5

SC

with Q, 5≤SC≤F-1

Lead Screws Support Units 4 Standard GC Changes the machining on the 0 No machining of small Ordering Code SC7 Support Units Lead Screws

SC = 1mm increments

Change Support Side

Shaft End Machining

support side.

5≤G≤45

Q is selected from 10, 12 and 15

steps on the fixed side

When

Ordering Code

specified

the fixed side

P.115 machining is Qh7 G G = 1mm increments Standard NF No machining of small steps on P.115

GC-Q10-G20

Change L Ordering Code NF

Change the length of

5

Stop Plates / Position Indicators the support side shaft FC Change the length of the support Q Change dimensions Change dimensions of small Position Indicators Stop Plates /

end

side shaft end.

12≤FC≤30

of small steps on the

steps on the fixed side

fixed side

FC = 1mm increments

F, P = 1mm increments

P.119 FC 10.15 Ordering Code FC20 Recommended P FP 20≤F≤36 8≤P≤12 P.119

Ordering Code

E Only one of 1, 3, 4 and 5 can be selected. F FP-F36-P12

E Only one of 7, 8 and 9 can be selected.

Actuators E Only one of 0 and Q can be selected. W Recommended EU Change dimensions of big steps Actuators

Change dimensions of big

steps on the fixed side

E When W and e are specified simultaneously, no male thread will be machined

on the fixed side

13≤E≤60 10≤U≤E-3

regardless of the value specified for U in W.

Ordering Code

Please reconfirm.

P.131 E When W or e is specified, the recommended support unit may not be available. U E, U = 1mm increments P.131

E When specifying any alteration, the nut motion range (Y dimension) may

EU-E60-U20

become shorter. Please make sure that the nut motion range is greater than the E

full length of the nut. e No machining of big

steps male thread on

the fixed side No machining of big steps male

Standard NU thread on the fixed side

Ordering Code NU

Change

Register an Account Technical Support Sales Inquiry Contact Us:

Tel: (65) 6733 7211

Website: sg.misumi-ec.com

Hours: 9am - 6pm (Mon - Fri) 72

bit.ly/RegisterMISUMIaccount techsupport@misumi.com.sg cs@misumi.com.sg 9am - 3pm (Sat)