Page 538 - MISUMI SINGAPORE Economy Series

P. 538

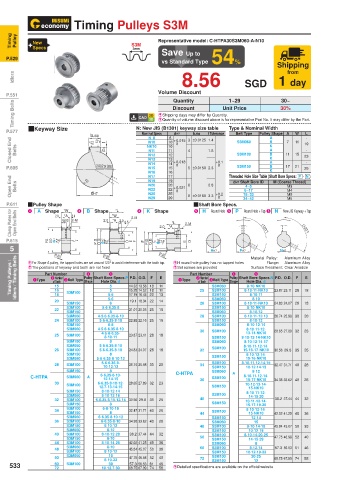

Timing Pulleys S3M

Timing Pulley New S3M Representative model: C-HTPA30S3M060-A-N10

Specs

3mm

Save Up to

P.529

vs Standard Type 54% Shipping

from

Idlers 8.56 SGD 1 day

Volume Discount

P.551 Quantity 1~29 30~

Timing Belts E Shipping days may differ by Quantity. 30%

Discount

Unit Price

E Quantity of volume discount above is for representative Part No. It may differ by the Part.

P.577 QKeyway Size N: New JIS (B1301) keyway size table Type & Nominal Width

t Tolerance

bJS9

dH7

bJS9 6.3 Nominal Specs 10 + 0.015 3 ±0.0125 1.4 Belt Type Pulley Shape A 7 W L -

N 8

8

A

Closed End Belts 6.3 6.3 t NK10 10 0 4 1.8 S3M100 K B K A 11 15 19 -

B

S3M060

11

N10

N11

11

N12

12

23

14

N14

0

0

P.605 2-R0.2 or Less N13 13 + 0.018 5 ±0.0150 2.3 +0.1 S3M150 B A 17 21 29 -

15

N15

K

N16 16 Threaded Hole Size Table (Shaft Bore Specs: P · N )

17

N17

Open End Belts 6.3 dH7 N19 19 + 0.021 6 2.8 +0.2 dH7 Shaft Bore ID M (Coarse Thread)

N20

20

M3

4~5

22

N22

M4

6~17

0

25

N25

M5

18~33

N29

0

M6

QShaft Bore Specs.

P.611 QPulley Shape *W 4 B Shape *L 4 K Shape 29 8 ±0.0180 3.3 Round Hole 5 P 34~42 N New JIS Keyway + Tap

A Shape

H

Clamp Plates for Open End Belts 2.0 W/2 2-M 2.0 *W 2.0 4.5 2-M 2.0 *A *L 5 2-M (120°) (120°)

Round Hole + Tap 5

5

4

*A

2.0

*A

P.615 P.D. O.D. dH7 6.3 E F P.D. O.D. dH7 6.3 D E F F P.D. O.D. E dH7 6.3 E D

5 HH7 PH7 NH7

(t1.0) (t1.0) (t1.0) E H round hole pulley has no tapped holes Material Pulley: Aluminum Alloy

Timing Pulleys / Idlers / Timing Belts E The positions of keyway and tooth are not fixed 5 14.32 13.56 18 11 E Set screws are provided Pulley Shaft Bore Specs.N P.D. O.D. F E

Aluminum Alloy

E For Shape A pulley, the tapped holes are set around 120° to avoid interference with the tooth top.

Flange:

Surface Treatment: Clear Anodize

4

4

Part Number

5

Part Number

F

E

Pulley Shaft Bore Specs.P P.D. O.D.

2 Number

2 Number

3Belt Type

1Type

1Type

3Belt Type

Shape

of Teeth

Hole Dia. d

Hole Dia. d

of Teeth

Shape

5

15

8·10·NK10

S3M060

5

16

8·10·11

S3M150

13

17.19 16.43 20

18

5·6

8·10

S3M060

20 S3M100 5·6 15.28 14.52 18 11 25 S3M100 8·10·11·NK10 23.87 23.11 28 18

19.1 18.34 22

14

24.83 24.07 28

S3M150

26

6

18

8·10·11·NK10

S3M100

22 S3M100 5·6·6.35·8 21.01 20.05 25 16 S3M150 8·10·NK10

S3M060

S3M150

8

8·10·12

S3M060 4·5·6·6.35·8·10 28 S3M100 8·10·11·12·13 26.74 25.98 30 20

24 S3M100 5·6·6.35·8·10 22.92 22.16 25 16 S3M150 8·10·12

S3M150 6·8 S3M060 8·10·12·14

S3M060 4·5·6·6.35·8·10 30 S3M100 8·10·11·12· 28.65 27.89 32 23

13·14·NK10

25 S3M100 4·5·6·6.35· 23.87 23.11 28 18 S3M150 8·10·12·14·NK10

8·10·11

S3M150 8 S3M060 8·10·12·14·17

S3M060 5·6·6.35·8·10 8·10·11·12·14·

26 S3M100 5·6·6.35·8·10 24.83 24.07 28 18 32 S3M100 15·16·17·NK10 30.56 29.8 35 25

S3M150 8 8·10·12·14·

S3M060 5·6·6.35·8·10·12 S3M150 15·16·NK10

28 S3M100 5·6·6.35·8· 26.74 25.98 30 20 34 S3M100 8·10·11·12·14·15 32.47 31.71 40 28

10·12·13

S3M150

10·12·14·15

S3M150 8 C-HTPA S3M060 A 8·12

C-HTPA S3M060 A 6·6.35·8·10· 36 S3M100 8·10·11·12·14· 34.38 33.62 40 28

12·14·15

15·17·NK10

30 S3M100 6·6.35·8·10·12· 28.65 27.89 32 23 S3M150 10·12·13·14·

12.7·13·14·15

15·NK10

S3M150 8·10·12·14 8·10·11·12·

S3M060 8·10·12·16 S3M100 14·15·20

32 S3M100 6·6.35·8·10·12·14 30.56 29.8 35 25 40 10·11·12·14· 38.2 37.44 44 32

S3M150 8 S3M150 15·17·19·20

34 S3M100 6·8·10·18 32.47 31.71 40 28 44 S3M100 8·10·12·14· 42.02 41.25 48 36

8

S3M150

15·NK10

S3M060 6·6.35·8·10·12 S3M150 12·14

36 S3M100 6·6.35·8·10 34.38 33.62 40 28 S3M060 15

S3M150 8·10·12 48 S3M100 8·10·14·15 45.84 45.07 50 38

S3M060 8·12 S3M150 10·12·19

40 S3M100 8·10·12·20 38.2 37.44 44 32 S3M100 8·10·14·20·25

S3M150 8·10 50 S3M150 14·15·29 47.75 46.98 52 40

44 S3M100 8·10·14·25 42.02 41.25 48 36 S3M060 8

8·10

8·12·14

48 S3M060 8·10·12 45.84 45.07 50 38 60 S3M100 10·12·19·22 57.3 56.53 61 46

S3M100

S3M150

10

50 S3M060 8·10·22 47.75 46.98 52 40 72 S3M100 20·25 68.75 67.99 74 58

12

S3M150

30

533 60 S3M100 10·12.7·30 57.3 56.53 61 46 EDetailed specifications are available on the official website

58

68.75 67.99 74

72