Page 227 - MISUMI SINGAPORE Economy Series

P. 227

1 1

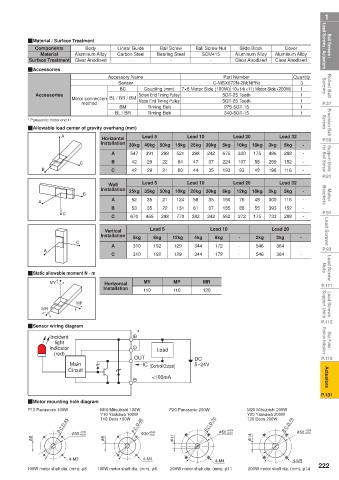

Ball Screws / Lead Screws / Actuators QMaterial / Surface Treatment Carbon Steel Bearing Steel Ball Screw Nut Aluminum Alloy Aluminum Alloy Lead Screws / Actuators Ball Screws /

Slide Block

Components

Linear Guide

Ball Screw

Body

Cover

Material

SCM415

Aluminum Alloy

-

Surface Treatment

Clear Anodized

Clear Anodized

Clear Anodized

-

-

Rolled Ball Screws QAccessories Accessory Name Coupling (mm) 7×8 Motor Side (100W) 10×14(×11) Motor Side (200W) Quantity Screws Rolled Ball

Part Number

3

Sensor

C-MSX672N-2M(NPN)

1

BC

Motor End Timing Pulley

5GT-25 Teeth

P.37 Accessories Motor connection BL / BR / BM Screw End Timing Pulley 5GT-25 Teeth 1 1 1 1 P.37

method

Timing Belt

BM

275-5GT-15

Precision Ball Screws * Panasonic: motor end 11 Screws Precision Ball

BL / BR

340-5GT-15

Timing Belt

QAllowable load center of gravity overhang (mm)

Horizontal

P.59 A Installation 30kg Lead 5 50kg 15kg Lead 10 30kg 5kg Lead 20 18kg 3kg Lead 32 - P.59

40kg

5kg

25kg

10kg

Support Units for Ball Screw C A 547 391 298 521 298 242 675 330 175 486 288 - - for Ball Screw Support Units

B

259

224

107

22

55

152

47

29

84

42

37

P.81 B C 42 29 21 80 44 35 193 93 48 198 116 - P.81

Wall Lead 5 Lead 10 Lead 20 Lead 32

Installation

Motor Brackets B A 25kg 35kg 50kg 10kg 20kg 30kg 6kg 12kg 18kg 2kg 5kg - - Brackets Motor

160

21

124

35

58

300

52

116

48

76

35

A

B 53 35 22 131 61 37 185 88 55 393 152 -

P.91 C C 670 455 298 770 382 242 562 272 175 733 288 - P.91

Lead Screws Installation 5kg Lead 5 12kg 4kg Lead 10 - 2kg Lead 20 - Lead Screws

Vertical

3kg

8kg

8kg

P.93 A C A 310 192 129 344 172 - - 546 364 - - P.93

172

192

310

364

C

129

344

546

Lead Screw Nuts QStatic allowable moment N · m Nuts Lead Screw

MY

Horizontal

P.111 MY Installation 110 MP MR P.111

120

110

Lead Screws Support Units MR MP Support Units Lead Screws

P.115 P.115

QSensor wiring diagram *

Stop Plates / Position Indicators indicator Load Position Indicators Stop Plates /

Incident

light

P.119 (red) OUT DC P.119

Main IC (Control Output) 5~24V

Circuit

Actuators <100mA Actuators

P.131 P.131

QMotor mounting hole diagram

P10 Panasonic 100W M10 Mitsubishi 100W P20 Panasonic 200W M20 Mitsubishi 200W

Y10 Yaskawa 100W Y20 Yaskawa 200W

T10 Delta 100W

T20 Delta 200W

P.C.D.45 +0.04 P.C.D.46 +0.04 P.C.D.70 +0.04 P.C.D.70 +0.04

φ 8 φ 30 +0.01 φ 8 φ 30 +0.01 φ 11 φ 50 +0.01 φ 14 φ 50 +0.01

4-M3 4-M4 4-M4 4-M5

100W motor shaft dia. (mm): φ8 100W motor shaft dia. (mm): φ8 200W motor shaft dia. (mm): φ11 200W motor shaft dia. (mm): φ14 222