Page 813 - MISUMI SINGAPORE Economy Series

P. 813

Economy series Product Overview Product Overview Economy series

Motorized Goniometer Stages Motorized Goniometer Stages

Installation method

When the upper plate is slid to CW or CCW side, 2 counterbored

holes are visible (4 holes in total). When a sine motion stage is

driven through the controller, the limit sensor works, but there is

no guarantee for the detection of mounting holes. Be sure to

manually expose the mounting holes and secure with the

supplied bolts.

Please pay attention to the above instructions. [Reference

standard of flatness: 10μm or less]

About objects mounted on the top / bottom of the stage

If an object with an uneven surface is mounted or the stage is

mounted on an uneven surface, the stage surface may be

deformed and accuracy may be affected. 9

Please pay attention to the above instructions. [Reference

standard of flatness: 10μm or less]

About installation posture of positioning stage

The horizontal installation of the stage is a prerequisite for the Screws / Positioning Stages Locating Pins / Bushings / Clamping

performance parameters of each product.

Be careful when using a product that is mounted upside down,

to the side (vertically or horizontally), or in any posture other

than on a level surface.

The load capacity and accuracy may vary greatly with the

installation posture. Pins Locating

For Product Features by Posture information, pleas refer to below

table:

P.745

▼Table of Product Features by Posture

Part Number Movable guide (feeding method) Upside-down use Side (horizontal) use Side (vertical) use

E-GMPG Cross roller G G G Locating Pins Bushings for

E-GMPWG (ball screw) Upside-down mounting

O Usable, with restrictions on load and torque. P.749

Side (vertical) mounting

QAbout Swing Accuracy and Height of Rotation Center Bolts Adjusting

Our cross roller type goniometer stages have a very small swing around the center of rotation and high accuracy.

P.753

Swing accuracy of rotation center

Place a steel ball at the height of the center of rotation (the actual center of rotation, not the theoretical

point in the design), and use the amount of swing (X.Y.Z) of the ball during the full stroke movement as the

swing accuracy of the rotation center. Screws Clamp

Height of rotation center (interval between workpieces) P.760

The height of rotation center is the distance between the top of the stage and the center of the steel ball of the guide.

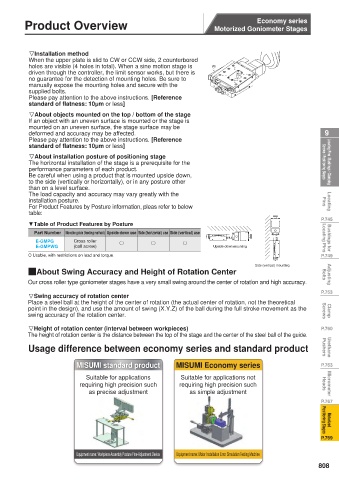

Usage difference between economy series and standard product Pushers Urethane

MISUMI standard product MISUMI Economy series P.763

Suitable for applications Suitable for applications not

requiring high precision such requiring high precision such Heads Micrometer

as precise adjustment as simple adjustment

P.767

Motorized

Positioning Stages

P.769

Equipment name: Workpiece Assembly Posture Fine-Adjustment Device Equipment name: Motor Installation Error Simulation Testing Machine

808