Page 514 - MISUMI SINGAPORE Economy Series

P. 514

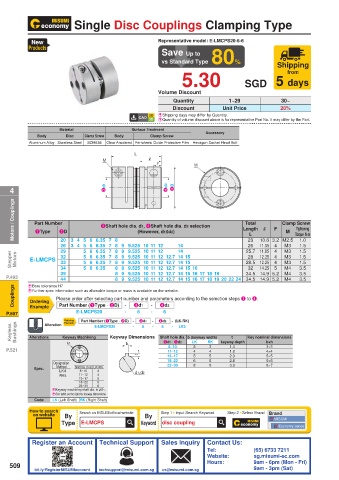

Single Disc Couplings Clamping Type

New Representative model: E-LMCPS20-6-6

Products

Save Up to

vs Standard Type 80% Shipping

5.30 SGD 5 days

from

Volume Discount

Quantity 1~29 30~

Discount Unit Price 20%

E Shipping days may differ by Quantity.

E Quantity of volume discount above is for representative Part No. It may differ by the Part.

Material Surface Treatment Accessory

Body Disc Clamp Screw Body Clamp Screw

Aluminum Alloy Stainless Steel SCM435 Clear Anodized Ferroferric Oxide Protective Film Hexagon Socket Head Bolt

L

M L

F M

4 3d1 4d2 2D

Motors / Couplings Part Number 3Shaft hole dia. d1, 4Shaft hole dia. d2 selection Length L F Clamp Screw

Total

Tightening

(However, d1≤d2)

2D

1Type

M

L

23

20

1.0

10.6 3.2 M2.5

26

1.5

3 4 5 6 6.35 7 8 9 9.525 10 11 12

26 3 4 5 6 6.35 7 8 14 25.7 11.35 4 4 M3 Torque N·m

5 6 6.35 7 8 9 9.525 10 11 12

M3

14

11.85

1.5

29

Stepper Motors E-LMCPS 32 5 6 6.35 7 8 9 9.525 10 11 12 12.7 14 15 28.5 12.25 4 4 M3 1.5

12.25

28

5 6 6.35 7 8 9 9.525 10 11 12 12.7 14 15

33

M3

1.5

32

34

14.9 5.2

M4

3.5

8 9 9.525 10 11 12 12.7 14 15 16 17 18 19

39 5 6 6.35 8 9 9.525 10 11 12 12.7 14 15 16 34.5 14.25 5 M4 3.5

P.493 EBore tolerance H7 44 8 9 9.525 10 11 12 12.7 14 15 16 17 18 19 20 22 24 34.5 14.9 5.2 M4 3.5

Couplings EFurther spec information such as allowable torque or mass is available on the website.

Please order after selecting part number and parameters according to the selection steps 1 to 4.

Ordering

6

6

E-LMCPS20

P.507 Example Part Number (1Type · 2D) - - 3d1 - - 4d2

Ordering Part Number (1Type · 2D) - - 3d1 - - 4d2 - (LK·RK)

Example

Keyless Bushings Alterations Keyway Machining Keyway Dimensions Shaft hole dia. b (keyway width) t Key nominal dimensions

Alteration

LK3

8

E-LMCPS20

-

8

3×3

3

1.4

3

8~10

P.521 M b 3d1 · 4d2 LK RK keyway depth b×h

4×4

11~12

1.8

4

4

13~17 5 5 2.3 5×5

t

18~22 6 6 2.8 6×6

Designation 23~30 8 8 3.3 8×7

Spec. Method Shaft Dia. d1·d2 LK·RK

LK4 8~10 3 d1,d2

RK4 11~12 4

13~17 5

18~22 6

23~30 8

EKeyway machining shaft dia. is φ8~.

ESee table on the right for keyway dimensions.

Code LK (Left Shaft) RK (Right Shaft)

How to search Search on MISUMI official website Step 1 Input Search Keyword Step 2 Select Brand Brand

on website By By

Type E-LMCPS Keyword disc coupling MISUMI

Economy series

Register an Account Technical Support Sales Inquiry Contact Us:

Tel: (65) 6733 7211

Website: sg.misumi-ec.com

509 Hours: 9am - 6pm (Mon - Fri)

bit.ly/RegisterMISUMIaccount techsupport@misumi.com.sg cs@misumi.com.sg 9am - 3pm (Sat)