Page 393 - MISUMI SINGAPORE Economy Series

P. 393

Economy Series Product Overview Product Overview Economy Series

Ball Splines Ball Splines

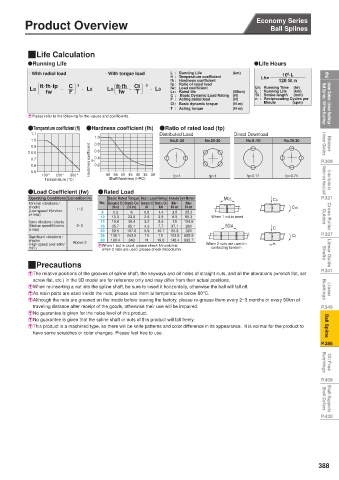

QLife Calculation

IRunning Life ILife Hours

2 · With radial load C 3 · With torque load 3 L : Running Life (km) Lh: Running Time (hr) 2

10 ·L

6

ft : Temperature coefficient

Lh=

120·St·n

fh : Hardness coefficient

Linear Guides / Linear Bushings / Ball Splines / Oil Free Bushings fw F · L0 fw T · L0 L0 : Rated life (50km) L : Running Life (km) Ball Splines / Oil Free Bushings Linear Guides / Linear Bushings /

fp : Ratio of rated load

ft·fh·fp

Ct

ft·fh

·

·

L=

L=

fw : Load coefficient

St : Stroke length

(mm)

C : Basic Dynamic Load Rating (N)

F : Acting radial load

n : Reciprocating Cycles per

(N)

(cpm)

Minute

(N·m)

Ct : Basic dynamic torque

T : Acting torque

(N·m)

EPlease refer to the following for the values and coefficients.

ITemperature coefficient (ft) IHardness coefficient (fh) IRatio of rated load (fp) Direct Download

1.1

Distributed Load

Miniature Linear Guides ft 1.0 1.0 No.8~20 No.25·30 No.8~20 No.25·30 Linear Guides Miniature

0.8

0.9

0.6

0.7

P.309 0.8 Hardness coefficient fh 0.4 P.309

0.2

0.6

Linear Guides for Medium and Heavy Load 0.5 100° 200° 300° 60 55 50 45 40 35 30 fp=1 fp=1 fp=0.71 fp=0.71 Medium and Heavy Load Linear Guides for

Shaft hardness (HRC)

Temperature (°C)

P.321 ILoad Coefficient (fw) IRated Load kN kN N·m N·m MO1 Co P.321

Operating Conditions Load coefficient (fw)

Basic Rated Torque Basic Load Rating Allowable Static Moment

M01

No. Dynamic Ct Static C0t Dynamic C Static C0

M02

Minimal vibrations /

Cross Roller Guides (Low speed 15m/min. 1~2 10 8 13.3 23.8 0.8 1.4 3.5 124.6 When 1 nut is used Cot Guides Cross Roller

shocks

(N·m)

(N·m)

6

25.2

3.3

or less)

9.5

2.6

3.9

85.3

15

3.2

5.4

36.4

19.6

13

Some vibrations / shocks

7.7

35.7

260

37.1

2~3

65.1

or less)

59.5

55.3

380

20

5.9

P.337 (Medium speed 60m/min. Above 3 16 135.1 107.8 4.3 10.7 103.5 685.9 MO2 C Ct P.337

15

243.6

10

25

Significant vibrations /

932.7

19.6

343

Linear Guide Shafts (High speed over 60m/ E When 1 nut is used, please check M01column; When 2 nuts are used in Shafts Linear Guide

148.4

11

30

190.4

shocks

contacting tandem

min.)

when 2 nuts are used, please check M02column.

P.341 QPrecautions P.341

E The relative positions of the grooves of spline shaft, the keyways and oil holes of straight nuts, and all the alterations (wrench flat, set

screw flat, etc.) in the 3D model are for reference only and may differ from their actual positions.

Linear Bushings E When re-inserting a nut into the spline shaft, be sure to insert it horizontally, otherwise the ball will fall off. Bushings Linear

E As resin parts are used inside the nuts, please use them at temperatures below 80°C.

traveling distance after receipt of the goods, otherwise their use will be impaired.

P.349 E Although the nuts are greased on the inside before leaving the factory, please re-grease them every 2~3 months or every 50km of P.349

ENo guarantee is given for the noise level of this product.

Ball Spline ENo guarantee is given that the spline shaft or nuts of this product will fall freely. Ball Spline

E This product is a machined type, so there will be knife patterns and color difference in its appearance. It is normal for the product to

have some scratches or color changes. Please feel free to use.

P.386 P.386

Oil Free Bushings Bushings Oil Free

P.409 P.409

Shaft Supports Shaft Collars Shaft Collars Shaft Supports

P.430 P.430

388