Page 348 - MISUMI SINGAPORE Economy Series

P. 348

Economy series Product Overview

Linear Shaft

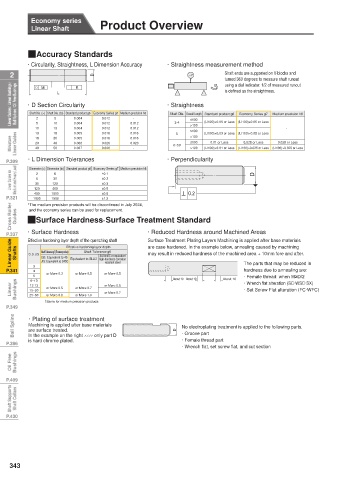

QAccuracy Standards

· Circularity, Straightness, L Dimension Accuracy · Straightness measurement method

2 M - K D Shaft ends are supported on V-blocks and 2

turned 360 degrees to measure shaft runout

Linear Guides / Linear Bushings / Ball Splines / Oil Free Bushings · D Section Circularity Medium precision h8 · Straightness is defined as the straightness. Medium precision h8 Ball Splines / Oil Free Bushings Linear Guides / Linear Bushings /

using a dial indicator. 1/2 of measured runout

L

Shaft Dia. (>) Shaft Dia. (to) Standard product g6 Economy Series g7

Economy Series g7

Shaft Dia. Overall Length Standard product g6

-

≤100

0.012

0.004

0.012

0.012

0.004

10 2 5 10 5 0.004 0.012 0.012 3·4 >100 (L/100)×0.05 or Less (L/100)×0.05 or Less -

13

≤100

(L/100)×0.03 or Less

0.016

18

0.016

0.005

13

(L/100)×0.05 or Less

5

Miniature Linear Guides 18 20 0.005 0.016 0.016 6~50 >100 (L/100)×0.01 or Less (L/100)×0.025 or Less (L/100)×0.025 or Less Linear Guides Miniature

0.025 or Less

0.025 or Less

≤100

0.01 or Less

40

0.020

0.020

0.006

20

0.007

50

>100

-

0.020

40

P.309 · L Dimension Tolerances · Perpendicularity P.309

Dimension (>) Dimension (to) Standard product g6 Economy Series g7 Medium precision h8

Linear Guides for Medium and Heavy Load 120 120 ±0.1 D Medium and Heavy Load Linear Guides for

2

6

6

30

±0.2

30

±0.3

±0.5

400

±0.8

1000

400

P.321 *The medium precision products will be discontinued in July 2024, 0.2 P.321

±1.2

1500

1000

Cross Roller Guides QSurface Hardness·Surface Treatment Standard Guides Cross Roller

and the economy series can be used for replacement.

P.337 · Surface Hardness · Reduced Hardness around Machined Areas P.337

Linear Guide Shafts O.D. (D) Shaft Tolerance g7 (Economy series) Effective hardening layer depth are case hardened. In the example below, annealing caused by machining Shafts Linear Guide

Effective hardening layer depth of the quenching shaft

Surface Treatment Plating Layers Machining is applied after base materials

Shaft Tolerance g6

may result in reduced hardness of the machined area + 10mm fore and after.

SUS440C or equivalent

GB: Equivalent to 45

Equivalent to SUJ2 high-hardness corrosion

JIS: Equivalent to S45C

hardness due to annealing are:

P.341 3 4 resistant steel The parts that may be reduced in P.341

5 or More 0.3 or More 0.5 or More 0.5 About 10 About 10 About 10 · Female thread: when M≥D/2

6~10

Linear Bushings 15~20 or More 0.5 or More 0.7 or More 0.5 · Wrench flat alteration (SC·WSC·SX) Bushings Linear

12·13

· Set Screw Flat alteration (FC·WFC)

or More 0.7

or More 1.0

or More 0.8

25~50

→ Same for medium precision products

P.349 P.349

Ball Spline Machining is applied after base materials D No electroplating treatment is applied to the following parts. Ball Spline

· Plating of surface treatment

are surface treated.

· Groove part

is hard chrome plated.

P.386 In the example on the right only part D · Female thread part P.386

· Wrench flat, set screw flat, and cut section

Oil Free Bushings Bushings Oil Free

P.409 P.409

Shaft Supports Shaft Collars Shaft Collars Shaft Supports

P.430 P.430

343