Page 295 - MISUMI SINGAPORE Economy Series

P. 295

1 1

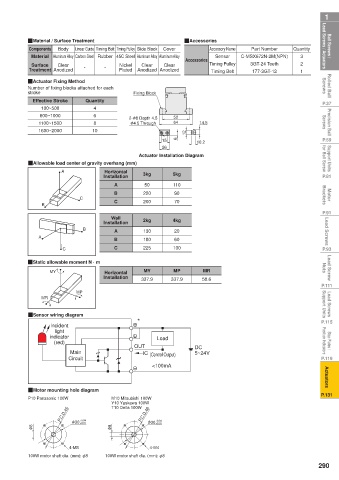

Ball Screws / Lead Screws / Actuators QMaterial / Surface Treatment Nickel Clear Cover QAccessories Sensor C-MSX672N-2M(NPN) Quantity Lead Screws / Actuators Ball Screws /

Accessory Name

Part Number

Body

Linear Guide Timing Belt Timing Pulley Slide Block

Components

Material Aluminum Alloy Carbon Steel Rubber 45C Steel Aluminum Alloy Aluminum Alloy

3

Accessories

3GT-24 Teeth

Timing Pulley

2

Surface

Clear

Clear

Anodized Anodized

Treatment Anodized

Rolled Ball Screws QActuator Fixing Method - - Plated Fixing Block Timing Belt 177-3GT-12 1 Screws Rolled Ball

Number of fixing blocks attached for each

stroke

P.37 Effective Stroke Quantity P.37

100~500

4

Precision Ball Screws 1100~1500 10 2- φ 8 Depth 4.5 52 14.5 Screws Precision Ball

6

600~1000

64

8

φ 4.5 Through

1600~2000

P.59 15 6 12 10.2 P.59

Support Units for Ball Screw QAllowable load center of gravity overhang (mm) Actuator Installation Diagram for Ball Screw Support Units

26

Horizontal

P.81 A Installation 3kg 5kg P.81

A 50 110

Motor Brackets C B 220 90 Brackets Motor

C

70

200

P.91 B Wall 2kg 4kg P.91

Lead Screws A B Installation 130 20 Lead Screws

A

180

60

B

P.93 C C 225 100 P.93

Lead Screw Nuts QStatic allowable moment N · m Horizontal MY MP MR Nuts Lead Screw

MY

P.111 MP Installation 337.9 337.9 58.6 P.111

Lead Screws Support Units MR Support Units Lead Screws

P.115 QSensor wiring diagram * P.115

Incident

light

Stop Plates / Position Indicators indicator OUT Load DC Position Indicators Stop Plates /

(red)

Main

P.119 Circuit IC (Control Output) 5~24V P.119

<100mA

Actuators Actuators

P.131 QMotor mounting hole diagram P.131

P10 Panasonic 100W M10 Mitsubishi 100W

Y10 Yaskawa 100W

T10 Delta 100W

P.C.D.45 +0.04 P.C.D.46

+0.01

φ 8 φ 30 +0.01 φ 8 φ 30 +0.04

4-M3 4-M4

100W motor shaft dia. (mm): φ8 100W motor shaft dia. (mm): φ8

290