Page 243 - MISUMI SINGAPORE Economy Series

P. 243

1 1

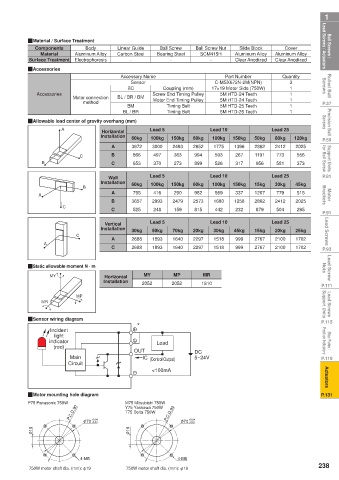

Ball Screws / Lead Screws / Actuators QMaterial / Surface Treatment Carbon Steel Bearing Steel Ball Screw Nut Aluminum Alloy Aluminum Alloy Lead Screws / Actuators Ball Screws /

Linear Guide

Ball Screw

Components

Cover

Slide Block

Body

Aluminum Alloy

Material

SCM415H

-

Clear Anodized

Clear Anodized

Electrophoresis

-

-

Surface Treatment

Rolled Ball Screws QAccessories Accessory Name Coupling (mm) 17×19 Motor Side (750W) Quantity Screws Rolled Ball

Part Number

3

Sensor

C-MSX672N-2M(NPN)

BC

1

Screw End Timing Pulley

5M HTD-24 Teeth

1

Accessories

method

P.37 Motor connection BL / BR / BM Motor End Timing Pulley 5M HTD-24 Teeth 1 1 1 P.37

Timing Belt

5M HTD-25 Teeth

BM

Precision Ball Screws QAllowable load center of gravity overhang (mm) Lead 5 Lead 10 Lead 25 Screws Precision Ball

5M HTD-25 Teeth

BL / BR

Timing Belt

A

Horizontal

P.59 Installation 60kg 100kg 150kg 60kg 100kg 150kg 50kg 80kg 120kg P.59

2025

2493

Support Units for Ball Screw B C B 866 497 363 994 593 267 1191 773 556 for Ball Screw Support Units

3000

3672

1396

2862

1775

2652

2412

A

899

370

653

273

C

581

373

956

526

317

P.81 Wall Lead 5 Lead 10 Lead 25 P.81

Installation 60kg 100kg 150kg 60kg 100kg 150kg 15kg 30kg 45kg

B

Motor Brackets A A 3657 2993 2479 2573 1680 1258 1207 2412 2025 Brackets Motor

337

779

290

982

569

515

416

795

2862

B

C C 525 248 159 815 442 232 879 504 295

P.91 Lead 5 Lead 10 Lead 25 P.91

Lead Screws C Installation 30kg 50kg 70kg 20kg 30kg 45kg 15kg 20kg 25kg Lead Screws

Vertical

2767

1518

2100

2688

1702

1640

1893

999

A

2297

P.93 A C 2688 1893 1640 2297 1518 999 2767 2100 1702 P.93

Lead Screw Nuts QStatic allowable moment N · m MY MP MR Nuts Lead Screw

MY

Horizontal

P.111 Installation 2052 2052 1810 P.111

Lead Screws Support Units MR MP Support Units Lead Screws

P.115 QSensor wiring diagram * P.115

Incident

Stop Plates / Position Indicators indicator Load Position Indicators Stop Plates /

light

(red)

5~24V

P.119 Main OUT IC (Control Output) DC P.119

Circuit <100mA

Actuators Actuators

P.131 QMotor mounting hole diagram P.131

P75 Panasonic 750W M75 Mitsubishi 750W

P.C.D.90 Y75 Yaskawa 750W P.C.D.90

T75 Delta 750W

+0.04

+0.04

φ 70 +0.01 φ 70 +0.01

φ 19 φ 19

4-M5 4-M6

238

750W motor shaft dia. (mm): φ19 750W motor shaft dia. (mm): φ19