Page 759 - MISUMI SINGAPORE Economy Series

P. 759

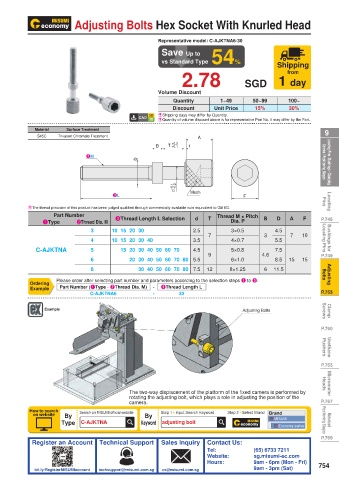

Economy series Product Overview Adjusting Bolts Hex Socket With Knurled Head

Adjusting Bolts

Representative model: C-AJKTNA6-30

Save Up to

vs Standard Type vs Standard Type 54%

Economy series Saving 2.78 Shipping

from

up to

Adjusting Bolts 54 % Volume Discount SGD 1 day

Quantity 1~49 50~99 100~

Smooth assembly Discount Unit Price 15% 30%

E Shipping days may differ by Quantity.

High precision thread E Quantity of volume discount above is for representative Part No. It may differ by the Part.

Material Surface Treatment 9

Excellent anti-rust performance S45C Trivalent Chromate Treatment A

+0.2

B T +0.1 1

2M

D Screws / Positioning Stages Locating Pins / Bushings / Clamping

QAdjusting Bolt Overview d -0.1 -0.2

3L Mesh F

· The adjusting bolt is often used together with E The thread precision of this product has been judged qualified through commercially available nuts equivalent to GB 6G. Pins Locating

the fixing block for the adjusting bolt. Part Number 3Thread Length L Selection d T Thread M × Pitch B D A F P.745

· Thread connecting positioning stage for front 1Type 2Thread Dia. M Dia. P

and rear position adjustment 3 10 15 20 30 2.5 7 3×0.5 3 4.5 7 10

· The adjustment method is generally divided 4 10 15 20 30 40 3.5 4×0.7 5.5 Locating Pins Bushings for

into two types: C-AJKTNA 5 15 20 30 40 50 60 70 4.5 5×0.8 7.5

1 Manual adjustment with knurling at low load 6 20 30 40 50 60 70 80 5.5 9 6×1.0 4.6 8.5 15 15 P.749

2 Adjustment with hex wrench at high load 8 30 40 50 60 70 80 7.5 12 8×1.25 6 11.5

* This design allows to use the Bolts

adjusting bolt to simply adjust the Adjusting

mechanism in XYZ direction. Ordering Please order after selecting part number and parameters according to the selection steps 1 to 3.

Example Part Number (1Type · 2Thread Dia. M) - 3Thread Length L

C-AJKTNA6 - 30 P.753

QCustomer Voice

1 For outgoing processed products, it often happens that the adjusting block cannot be installed because Example Adjusting Bolts Screws Clamp

the groove outer diameter or groove width is poor.

2 The thread accuracy is not good, sometimes not smooth enough in the adjustment and sometimes too loose.

3 Most surface treatment of outgoing processed products is blackened with poor rust prevention performance. P.760

1 Guaranteed groove tolerance for smooth assembly 2 High precision thread

Guaranteed accuracy T +0.2 Generic products on the market MISUMI Economy series Pushers Urethane

+0.1

tolerance of groove width · No inspection standard · Full inspection before shipment

and groove outer diameter · During assembly, the thread is often · Ensure smooth P.763

too tight and cannot be screwed adjustment during use

* Problems of generic products on the market.

-0.1 -0.2 Heads Micrometer

d The two-way displacement of the platform of the fixed camera is performed by

rotating the adjusting bolt, which plays a role in adjusting the position of the

3 Excellent anti-rust performance camera. P.767

How to search Search on MISUMI official website Step 1 Input Search Keyword Step 2 Select Brand Brand

24h Salt Spray Test Results on website By By MISUMI Positioning Stages Motorized

Blackened product severely rusted Trivalent chromate treatment with Type C-AJKTNA Keyword adjusting bolt Economy series

Full assembly slight white rust and no rusting

confirmation before shipment P.769

Ensure smooth assembly Register an Account Technical Support Sales Inquiry Contact Us:

with the adjusting block Tel: (65) 6733 7211

* Generic products on the market are similar products randomly purchased

by our company from online or offline markets Website: sg.misumi-ec.com

* The test data are obtained through testing by our company, which are for reference only. Hours: 9am - 6pm (Mon - Fri) 754

bit.ly/RegisterMISUMIaccount techsupport@misumi.com.sg cs@misumi.com.sg 9am - 3pm (Sat)