Page 315 - MISUMI SINGAPORE Economy Series

P. 315

Economy Series Product Overview Product Overview Economy Series

Miniature Linear Guides Miniature Linear Guides

vs Standard Type QInstallation of guide rail

Saving

Economy Series up to IWhen there is a reference surface in the base mounting surface

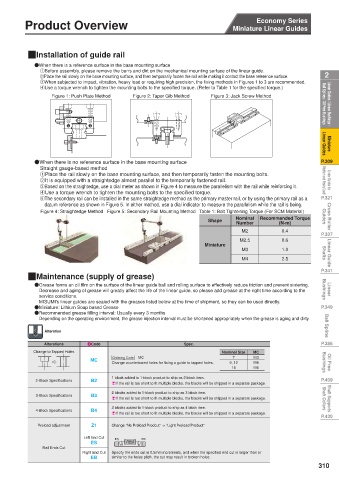

1Before assembly, please remove the burrs and dirt on the mechanical mounting surface of the linear guide.

2 Standard Grade Precision 59 % 2Place the rail slowly on the base mounting surface, and then temporarily fasten the rail while making it contact the base reference surface. 2

3When subjected to impact, vibration, heavy load or requiring high precision, the fixing methods in Figures 1 to 3 are recommended.

Linear Guides / Linear Bushings / Ball Splines / Oil Free Bushings Miniature Linear Guides Figure 1: Push Plate Method Figure 2: Taper Gib Method Figure 3: Jack Screw Method Ball Splines / Oil Free Bushings Linear Guides / Linear Bushings /

improved

4Use a torque wrench to tighten the mounting bolts to the specified torque. (Refer to Table 1 for the specified torque.)

Miniature Linear Guides Precision improved Good smoothness Linear Guides Miniature

P.309 IWhen there is no reference surface in the base mounting surface P.309

Straight gauge-based method

Linear Guides for Medium and Heavy Load EActual product's color may be slightly different with photo. 1Place the rail slowly on the base mounting surface, and then temporarily fasten the mounting bolts. Medium and Heavy Load Linear Guides for

2It is equipped with a straightedge almost parallel to the temporarily fastened rail.

3Based on the straightedge, use a dial meter as shown in Figure 4 to measure the parallelism with the rail while reinforcing it.

P.321 QSpecification Comparison QDimensional Precision 4Use a torque wrench to tighten the mounting bolts to the specified torque. P.321

5 The secondary rail can be installed in the same straightedge method as the primary master rail, or by using the primary rail as a

· Through enhanced management of the dimensional

Reference side

datum reference as shown in Figure 5. In either method, use a dial indicator to measure the parallelism while the rail is being.

Cross Roller Guides tolerance of the ball return hole and the steel ball, H Figure 4: Straightedge Method Figure 5: Secondary Rail Mounting Method Table 1: Bolt Tightening Torque (For SCM Material) Guides Cross Roller

the clearance dimension K is reduced and the

Nominal Recommended Torque

Shape

noise is reduced.

Number

(N·m)

Guide Rail

M2

P.337 Side sealing gasket Block Ball-return hole M2.5 0.4 P.337

Return Cap

0.6

Linear Guide Shafts Ball K Unit: μm Economy series product Standard product Miniature M3 1.0 Shafts Linear Guide

N

2.5

M4

Precision Standard

P.341 Retainer (Wire) Steel Ball Height H Tolerance ±20 ±20 P.341

Wide Rail

Rail Block Short Standard rail Long Standard Long Height H Pair Variation ±25 ±25 QMaintenance (supply of grease)

40

40

Width N Tolerance

Standard

Linear Bushings Smoothness Good Good Good Good Good Width N Pair Variation Low and medium frequency drive High frequency drive I Grease forms an oil film on the surface of the linear guide ball and rolling surface to effectively reduce friction and prevent sintering. Bushings Linear

40

40

Decrease and aging of grease will greatly affect the life of the linear guide, so please add grease at the right time according to the

60db

62db

52db

52db

50db

Applications

Noise

*The precision of the Economy series products has been improved service conditions.

MISUMI's linear guides are sealed with the greases listed below at the time of shipment, so they can be used directly.

P.349 compared to the year 2022. IMiniature: Lithium Soap based Grease P.349

QMovement Parallelism I Recommended grease filling interval: Usually every 3 months

Ball Spline Rail length Parallelism μm Rail length Parallelism μm Depending on the operating environment, the grease injection interval must be shortened appropriately when the grease is aging and dirty. Ball Spline

17

250~315

12

50 or Less

Alteration

50~80

P.386 125~200 13 315~400 18 Change to Tapped Holes 4Code Spec. Nominal Size MC P.386

Alterations

19

80~125

14

400~500

20

500~630

15

Oil Free Bushings 200~250 16 630~800 22 MC Change counterbored holes for fixing a guide to tapped holes. 9, 12 M3 Bushings Oil Free

7

Ordering Code MC

M4

800~900

23

15

M5

P.409 2-Block Specifications B2 1 block added to 1-block product to ship as 2 block item. P.409

E If the rail is too short to fit multiple blocks, the blocks will be shipped in a separate package.

Shaft Supports Shaft Collars 3-Block Specifications B3 2 blocks added to 1-block product to ship as 3 block item. Shaft Collars Shaft Supports

E If the rail is too short to fit multiple blocks, the blocks will be shipped in a separate package.

E If the rail is too short to fit multiple blocks, the blocks will be shipped in a separate package.

P.430 4-Block Specifications B4 3 blocks added to 1-block product to ship as 4 block item. P.430

Preload adjustment Z1 Change “No Preload Prodcut” -> “Light Preload Product”

Left End Cut ES EB

ES Engraving

Rail Ends Cut

ENote for anti-rust treatment: If products made of carbon steel are selected, anti-rust treatment is required during the process of unpacking, installation and use. Right End Cut Specify the ends cut in 0.5mm increments, and when the specified end cut is larger than or

EWear gloves during installation, and apply displacing type rust preventive oil on the surface of the guide after the installation is completed. EB similar to the holes pitch, the cut may result in broken holes.

ERust prevention maintenance should be part of routine spot checks and maintenance of the equipment. 310