Page 1588 - MISUMI SINGAPORE Economy Series

P. 1588

[Materials]

Hardening and Hardness Test Methods

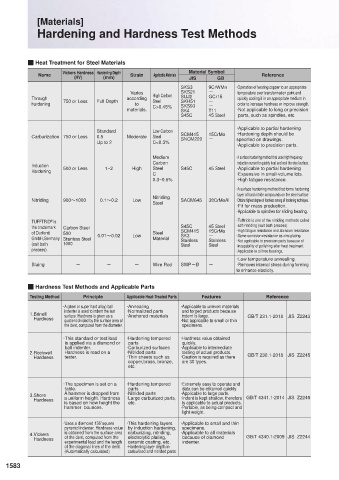

Q Heat Treatment for Steel Materials

Name Vickers Hardness Hardening Depth Strain Applicable Materials Material Symbol Reference

(mm)

(HV)

JIS

GB

SKS3 9CrWMn · Operation of heating copper to an appropriate

Varies SKS21 - temperature over transformation point and

Through according High Carbon SUJ2 GCr15 quickly cooling it in an appropriate medium in

hardening 750 or Less Full Depth to Steel SKH51 - order to increase hardness or improve strength.

SKS93

C>0.45%

-

materials. SK4 T11 · Not applicable to long or precision

S45C 45 Steel parts, such as spindles, etc.

·Applicable to partial hardening

Standard Low Carbon

Carburization 750 or Less 0.5 Moderate Steel SCM415 15CrMo ·Hardening depth should be

SNCM220

Up to 2 C<0.3% - specified on drawings.

·Applicable to precision parts.

Medium · A surface hardening method that uses high frequency

Induction Carbon induction current to quickly heat and cool the steel surface.

Hardening 500 or Less 1~2 High Steel S45C 45 Steel ·Applicable to partial hardening

C ·Expensive in small-volume lots.

0.3~0.5% ·High fatigue resistance.

· A surface hardening method that forms hardening

layer of hard nitride compounds on the steel surface

Nitriding

Nitriding 900~1000 0.1~0.2 Low SACM645 38CrMoAl ·Obtains highest degree of hardness among all hardening techniques.

Steel

·Fit for mass production.

·Applicable to spindles for sliding bearing.

TUFFTRID is · Tufftride is one of the nitriding methods called

®

the trademark Carbon Steel S45C 45 Steel soft-nitriding (salt bath process).

of Durferrit 500 Steel SCM415 15CrMo · High fatigue resistance and abrasion resistance

GmbH‚Germany Stainless Steel 0.01~0.02 Low Material SK3 - · Same corrosion resistance as zinc plating.

Stainless

Stainless

· Not applicable to precision parts because of

(salt bath 1000 Steel Steel incapability of polishing after heat treatment.

process). ·Applicable to oil free bearings.

·Low temperature annealing.

Bluing - - - Wire Rod SWP-B - ·Removes internal stress during forming

to enhance elasticity.

Q Hardness Test Methods and Applicable Parts

Testing Method Principle Applicable Heat-Treated Parts Features Reference

· A (steel or super hard alloy) ball ·Annealing · Applicable to uneven materials

1. Brinell indenter is used to indent the test ·Normalized parts and forged products because GB/T 231.1-2018 JIS Z2243

indent is large.

·Anchored materials

surface. Hardness is given as a

Hardness quotient divided by the surface area of · Not applicable to small or thin

the dent, computed from the diameter. specimens.

· This standard or test load · Hardening tempered · Hardness value obtained

is applied via a diamond or parts quickly.

ball indenter. ·Carburized surfaces · Applicable to intermediate

2. Rockwell Hardness is read on a ·Nitrided parts testing of actual products.

Hardness tester. · Thin sheets such as · Caution is required as there GB/T 230.1-2018 JIS Z2245

copper,brass, bronze, are 30 types.

etc.

· The specimen is set on a · Hardening tempered · Extremely easy to operate and

table. parts data can be obtained quickly.

3. Shore A hammer is dropped from ·Nitrided parts ·Applicable to large parts.

· Large carburized parts, · Indent is kept shallow, therefore GB/T 4341.1-2014 JIS Z2246

Hardness a uniform height. Hardness

is based on how height the etc. is applicable to actual products.

hammer bounces. · Portable, as being compact and

light weight.

· Uses a diamond 136˚square · This hardening layers · Applicable to small and thin

pyramid indenter. Hardness value by induction hardening, specimens.

4. Vickers is obtained from the surface area carburizing, nitriding, · Applicable to all materials

Hardness of the dent, computed from the electrolytic plating, because of diamond GB/T 4340.1-2009 JIS Z2244

experimental load and the length ceramic coating, etc. indenter.

of the diagonal lines of the dent. · Hardening layer depth in

(Automatically calculated) carburized and nitrided parts.

1583 1584