Page 575 - MISUMI SINGAPORE Economy Series

P. 575

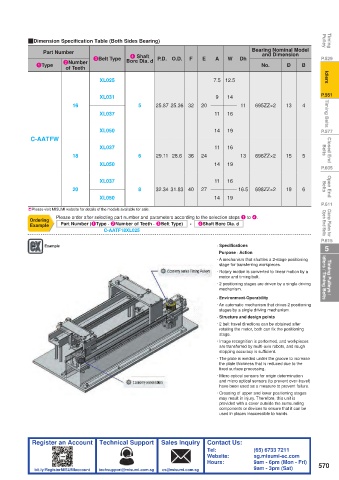

QDimension Specification Table (Both Sides Bearing) Pulley Timing

Part Number Bearing Nominal Model

and Dimension

4 Shaft

3Belt Type Bore Dia. d P.D. O.D. F E A W Dh P.529

1Type 2Number No. D B

of Teeth

XL025 7.5 12.5 Idlers

XL031 9 14 P.551

16 5 25.87 25.36 32 20 11 695ZZ×2 13 4

XL037 11 16 Timing Belts

XL050 14 19 P.577

C-AATFW

XL037 11 16 Belts

18 6 29.11 28.6 36 24 13 696ZZ×2 15 5 Closed End

XL050 14 19

P.605

XL037 11 16

20 8 32.34 31.83 40 27 16.5 698ZZ×2 19 6 Belts Open End

XL050 14 19

P.611

E Please visit MISUMI website for details of the models available for sale.

Please order after selecting part number and parameters according to the selection steps 1 to 4.

Ordering

Example Part Number (1Type · 2Number of Teeth · 3Belt Type) - 4Shaft Bore Dia. d Open End Belts Clamp Plates for

C-AATF18XL025

P.615

Example · Specifications 5

Purpose · Action

· A mechanism that shuttles a 2-stage positioning

stage for transferring workpieces.

· Rotary motion is converted to linear motion by a

motor and timing belt. Idlers / Timing Belts Timing Pulleys /

· 2 positioning stages are driven by a single driving

mechanism.

· Environment·Operability

· An automatic mechanism that drives 2 positioning

stages by a single driving mechanism.

· Structure and design points

· 2 belt travel directions can be obtained after

rotating the motor, both can fix the positioning

stage.

· Image recognition is performed, and workpieces

are transferred by multi-axis robots, and rough

stopping accuracy is sufficient.

· The plate is welded under the groove to increase

the plate thickness that is reduced due to the

fixed surface processing.

· Micro optical sensors for origin determination

and micro optical sensors (to prevent over-travel)

have been used as a measure to prevent failure.

· Crossing of upper and lower positioning stages

may result in injury. Therefore, this unit is

provided with a cover outside the surrounding

components or devices to ensure that it can be

used in places inaccessible to hands.

Register an Account Technical Support Sales Inquiry Contact Us:

Tel: (65) 6733 7211

Website: sg.misumi-ec.com

Hours: 9am - 6pm (Mon - Fri) 570

bit.ly/RegisterMISUMIaccount techsupport@misumi.com.sg cs@misumi.com.sg 9am - 3pm (Sat)